Climate Risk Management

Responsible Organization

The Technology Strategy Office, which reports directly to the CEO, is responsible for developing decarbonization plans for the steel business and advancing the transition to a carbon reduction production system through investments in electric arc furnace (EAF) facilities. The Environmental & Energy Planning Office oversees responses to domestic and international carbon regulations—such as the Carbon Border Adjustment Mechanism (CBAM)—as well as energy policies and third-party greenhouse gas assessments.

Analysis of Climate-Related Risks and Opportunities

| Category | Risks and Opportunities | Description | Response Measures | ||

|---|---|---|---|---|---|

| Risks | Transition Risk | Policy and Legal Risks | Strengthening of ETS and Reduction of Gratuitous Allocation | Rising carbon costs from reduced free allocation and higher auctioning ratio |

• Introduce an internal carbon pricing system • Establish greenhouse gas forecasting and reduction plans • Develop bridge technologies for blast furnaces |

| Full Enforcement of EU Carbon Border Adjustment Mechanism (CBAM) | Steel exports to face CBAM burden from 2026 |

• Operate a dedicated task force to respond to CBAM • Commence construction of the 2.5 million-ton Gwangyang EAF • Develop advanced ironmaking technologies using EAF-based production |

|||

| Market Risks | Increased Demand for Carbon-Reduced Steel Supply | Timely response required to address the rising demand for carbon-reduced steel |

• Advance low hot metal ratio (HMR) and melted scrap charging technologies • Develop advanced ironmaking technologies using EAF-based production |

||

| Strengthened Competition in Global Raw Material Supply Chains | Intensifying global competition for pellet and HBI procurement |

• Review investment in HBI projects in Australia and the Middle East • Expand scrap collection bases and sorting centers |

|||

| Technology Risks | Risks in the development process of hydrogen reduction ironmaking technology | Rising demand for large-scale investments in HyREX development and long-term technology verification | • Construct a HyREX demonstration plant | ||

| Limitations in High-Grade EAF Steel Technology | Technical limitations in refining for high-grade EAF steel production | • Develop advanced ironmaking technologies using EAF-based production | |||

| Uncertainties in CCUS Process Technologies | Uncertainties in CCUS efficiency and battery process integration | • Expand demonstration capabilities through RIST-KEIT projects | |||

| Physical Risks | Acute Risks | Coastal Flooding and River Overflow Risks | Recurring flood risk in Pohang Naengcheon and Gwangyeong coastal areas | • Strengthen flood resilience with BCP planning, cutoff walls, and drainage infrastructure | |

| Opportunities | Transition | Products and Services | Growing Demand for Eco-Friendly Products | Rising product demand driven by EV and renewable energy industries | • Develop carbon-reduced steel, high-performance cathode materials, and RE100-certified products with expanded global certification |

| Resource Efficiency | Enhanced Use of Facility Efficiency, Scrap, and By-Product Gases | Potential for high-efficiency facilities and energy savings | • Optimize power generation and hot blast control, and expand recovery of by-product gases | ||

| Resilience | Reinforcement of Supply Chain and Energy Resilience | Need for systematic response to climate risks | • Accelerate RE100 transition through solar expansion, overseas power PPAs, and LNG-hydrogen co-firing | ||

Physical Risks

Methodology

The climate modeling analysis methodology of S&P Global Climate Economics applies Shared Socioeconomic Pathways (SSP) scenario, a new greenhouse gas pathways used in the Sixth Assessment Report of the IPCC1) (AR6, Working Group I). The scenarios incorporate socioeconomic factors such as future population changes, economic development, and urbanization alongside the Representative Concentration Pathway (RCP) scenarios.

1)Intergovernmental Panel on Climate Change

SSP Scenario

| Category | Scenario Applicable to Worksites | Global Temperature (at the End of the 21st Century) |

|---|---|---|

| SSP 1-2.6 |

A scenario in which the reduction of social inequality and the rapid development of eco-friendly technologies lead to climate change mitigation and the establishment of a carbon-reduced, sustainable socioeconomic structure capable of adapting to climate change. |

+1.9℃ |

| SSP 2-4.5 |

A scenario that assumes moderate economic growth and a mid-level stage of socioeconomic development. | +3.0℃ |

| SSP 3-7.0 |

A scenario characterized by imbalances in socioeconomic development and institutional limitations, resulting in a socioeconomic structure that is vulnerable to climate change. | +4.3°C |

SSP | A scenario without climate policies, based on fossil fuel-driven growth and high human capital investment—leading to a high-carbon socioeconomic structure with strong adaptive capacity but limited mitigation potential. | +5.2°C |

Target and Results

Projected Financial Impact of Physical Risks (2040–2049, Based on SSP 5-8.5 Scenario)

|

Worksite |

Abnormal Weather |

Inland Flooding (Heavy Rain) |

Coastal flooding |

Fluvial |

Drought |

Forest Fires |

Typhoons |

Water |

|---|---|---|---|---|---|---|---|---|

|

Pohang Works |

1-5% | 1% or lower |

1% or lower |

1% or |

1% or |

1% or |

1% or |

1% or |

|

Gwangyang Works |

1-5% | 1% or lower |

1% or lower |

1% or |

1% or |

1% or |

1% or |

1% or |

|

PT. KRAKATAU POSCO (Indonesia) |

1-5% |

1% or |

1% or |

1% or |

1% or |

1% or |

1% or |

1% or |

|

POSCO Zhangjiagang Pohang Stainless Steel (China) |

1-5% |

1% or |

1% or |

1% or |

1% or |

1% or |

1% or |

1% or |

|

POSCO YAMATO VINA (Vietnam) |

1-5% |

1% or |

1% or |

1% or |

1% or |

1% or |

1% or |

1% or |

Response Status

Current Status of Coastal Flooding Risk Response

| Worksite | Response Measures | Site Elevation (Relative to Sea Level) |

|---|---|---|

| Pohang Works |

· Installed breakwater retaining walls (2.3 km) at the raw material pier in tsunami-prone areas (2012–2017), and reinforced shore protection facilities1) and breakwaters2) (2020)

· Installed floodgates and flood barriers at 1,853 flood-prone locations within the steelworks and critical facilities

· Reinforced external flood walls around the steelworks (1.9 km) and along the Naengcheon Stream (1.7 km)

· Developed a monitoring and management system for the steelworks drainage network using water level gauges and CCTV, and improved the drainage infrastructure

· Deployed high-capacity engine pumps for emergency flood response

|

+3.2~4.5m |

| PT.Krakatau POSCO (Indonesia) |

· Constructed drainage facilities and improved drainage channels based on maximum daily rainfall estimates

· Installed floodgates and flood walls at critical facilities such as electrical rooms and ironmaking substations (96 locations)

|

+4.5~5.5m |

| POSCO YAMATO VINA (Vietnam) |

· Elevated major facilities—including electric arc furnaces, refining units, continuous casting lines, rolling mills, equipment rooms, and electrical rooms—to the 2nd or 3rd floor above ground level to mitigate coastal flood risks

· Expanded drainage channels near the port pier and product warehouse (March–October 2023), and conducted port dredging every two years

|

+3.7m |

1)A protective structure installed to prevent the erosion of boundary areas of rivers, coasts, and levees.

2)A breakwater constructed offshore to reduce wave energy.

Current Status of Fluvial Flooding Risk Response

| Worksite | Response Measures |

|---|---|

| Gwangyang Works | · Installed floodgates and flood walls in steelmaking and rolling areas (662 locations) · Developed a drainage management system for the steelworks and enhanced drainage capacity · Deployed large engine pumps for emergency flood response |

Just Transition

Executives and Employees

Local Communities

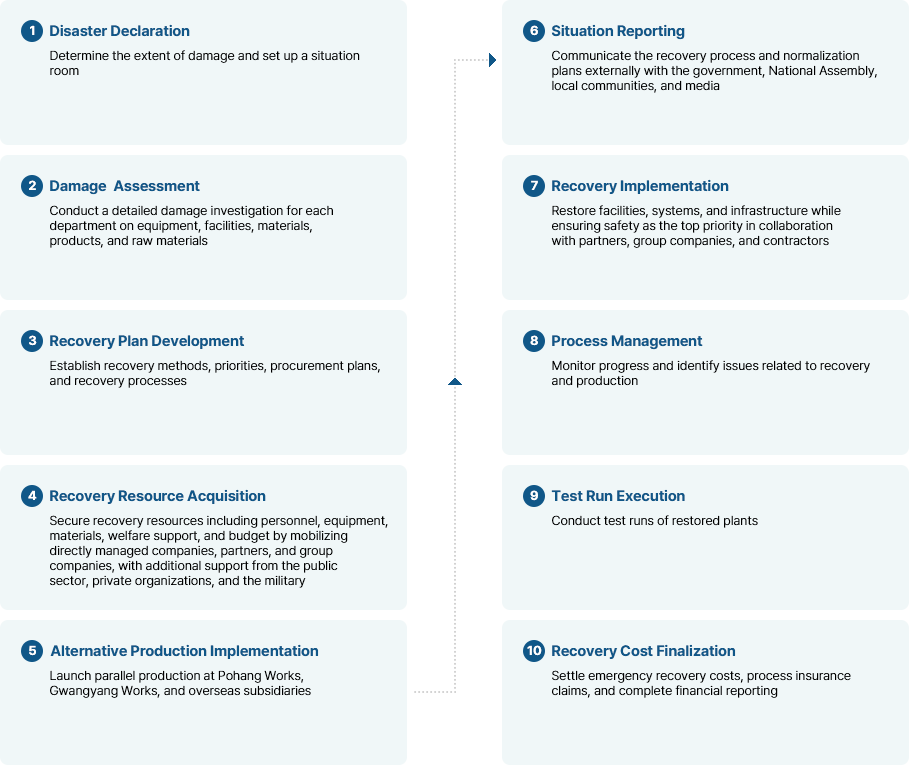

Physical Risk Response Process

Physical Risk Response Process for Disaster Management

Disaster Types

Disaster management system

| Category | Definition | Major Activities |

|---|---|---|

| Prevention | · Preventive activities conducted annually to prevent disaster-related damage | · Establish and inspect disaster management systems · Inspect and reinforce facilities · Provide disaster safety education and conduct emergency drills |

| Preparation | · Preparatory activities conducted approximately seven days before a disaster (D–7) to prevent disaster-related damage | · Procure emergency equipment and supplies · Manage disaster response measures by phase |

| Response | · Response activities conducted on the day of the disaster (D-0) to prevent disaster-related damage | · Issue alerts and activate the disaster response center · Implement initial response operations, including rescue and emergency medical activities |

|

Recovery |

· Activities to restore equipment, facilities, and core business functions damaged by a disaster |

· Form and operate recovery organizations |