Risk Management

Environmental Risk

POSCO identifies rapidly evolving market conditions and environmental regulations—both domestic and international—as potential risks and opportunities, recognizing their impact on corporate operations. These factors are reflected in our mid- to long-term business strategies and investment decisions. To address policy risks, we continuously monitor relevant regulations and policies, proactively identify potential threats, and actively participate in policy discussions to support rational and effective policy development.

We also conduct environmental impact assessments to determine key influencing factors and their level of impact, and implement appropriate mitigation measures to minimize environmental harm. In addition, environmental diagnostics are conducted by each plant’s environmental team to prevent risks such as environmental accidents or legal violations, and findings are regularly reported to the CEO through management meetings and executive briefings. Each steelworks also conducts daily environmental patrols to further reduce environmental impact and ensure rapid response to potential risks.

Water Risks

POSCO conducts annual reviews to assess whether its business sites are located in water-stressed or high-risk areas, and categorizes water risks to prioritize management at sites with high water stress or significant water withdrawal volumes.

In March 2024, POSCO signed a business agreement with the Ministry of Environment(MOE) to enhance joint responses to climate change and the water crisis, aiming to raise mutual awareness of water-related risks.

Gwangyang Works (High Water Stress)

As of August 2023, Gwangyang was confirmed to be located in a “High Water Stress” area according to the WRI’s 2023 Water Stress analysis. To mitigate risks such as reduced plant utilization due to water shortages, we have established a comprehensive response plan and maintain emergency measures in the event of supply restrictions.

Status Analysis

- As steelmaking operations run continuously year-round, it is critical to mitigate risks of unplanned shutdowns in core equipment such as blast furnaces and electric arc furnaces, which handle high-temperature materials.

- A water supply reduction of 5% or more from standard operating levels may lead to production bottlenecks and decreased throughput in downstream facilities, ultimately disrupting stable steel output and supply continuity.

Emergency Response to Water Shortages

- Based on projected water supply-to-capacity utilization scenarios, POSCO activates a phased emergency response when water supply falls below 10%. Measures include operating the seawater desalination facility at full capacity (30,000 tons/day) and maximizing the use of the freshwater reservoir (260,000 tons) to ensure a stable alternative water source.

【 Projected Water Supply-to-Capacity Utilization Scenario 】

| Water Supply | 100% | 95% | 89% | 84% | 79% |

| Capacity Utilization | 100% | 75% | 50% | 25% | 0% |

【 Emergency Response Organization Chart 】

Response Plan vs. Performance (2024)

・POSCO has established a water conservation plan to prepare for emergencies such as droughts and is building a cooperative framework with

relevant government agencies to ensure water security.

- Water Conservation Measures: In the event of a drought or other emergency, we aim to maximize the operation of seawater desalination

facilities—from 20,000 to 30,000 tons/day.

- Public-Private Partnership: Interagency Collaboration: In June 2024, POSCO Gwangyang Works signed a business agreement with the K-Water

(Yeosu) to secure a stable supply of industrial water. In the same month, we participated in a Water Sector Consultative Group led by the MOE.

In December 2024, we reached an agreement on the establishment of a regional water supply network for the Gwangyang Bay area, to be

led by the Yeongsan River Authority.

Pohang Works (Medium High Water Stress)

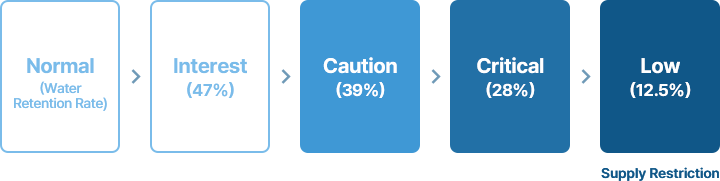

Water Storage-Based Response Plan for Yeongcheon Dam, POSCO’s Water Source

Emergency Response System for Water Supply Shortages

| Water Retention Rate | Response Plan |

|---|---|

| 28.0% or Less (Drought at a “Critical” Level) |

|

| 12.5% or Less (Water retention at a “Supply Restriction” Level) |

|

Labor-Management Joint Committee

- 2024 Results: Environmental issues were discussed biweekly, addressing a total of 23 cases.

Integrated Environmental Manager

Pro-Environment Consulting Section

In February 2021, POSCO established the Pro-Environment Consulting Section to lead comprehensive odor mitigation initiatives at Pohang Works.

This team conducts full-cycle improvement efforts—ranging from identifying odor sources to proposing technical solutions—leveraging POSCO’s expertise in facility operations and environmental enhancement technologies, in collaboration with Pohang City. Since its launch, the team has identified primary odor sources at facilities such as fertilizer manufacturers and steel subcomponent producers, assessed the performance of odor control equipment (e.g., scrubbers), and developed tailored improvement plans. Notably, to address odors at the source, we collaborated with the Research Institute of Industrial Science & Technology (RIST) to develop technologies that replace odor-generating raw materials with low-odor POSCO by-products, and to substitute conventional binders used in fertilizer manufacturing with odorless alternatives. The results of odor diagnoses and tailored improvement plans were shared with relevant companies and the City of Pohang through formal briefings. Based on these findings, each site upgraded its prevention systems—such as installing new scrubbers—and continues to test and adopt alternative low-odor raw materials.

Among the improvement measures proposed by the Pro-Environment Consulting Section, items requiring capital investment are being implemented at each site in conjunction with Pohang City’s SME-scale prevention facility support program. In 2024, POSCO entered into an agreement with Pohang City and local steelworks to encourage voluntary participation in odor reduction initiatives across steelmaking sites.

-

Voluntary Odor Improvement Agreement Ceremony for Pohang Steel Industrial Complex Worksites

-

Odor Diagnosis for Each Worksite

-

Odor Diagnosis Results Briefing

Environmental Education

In 2024, we conducted group training for ISO 14001 managers on environmental management system requirements and internal auditing techniques. Additionally, specialized training was provided to on-site personnel—including plant managers, steelwork team leaders, and staff in environment-related, investment, and maintenance departments—covering topics such as applicable environmental laws and regulations, prevention and response strategies for key environmental risks, and POSCO’s environmental management systems.

To further promote environmental awareness across the company, we also utilize the Labor-Management Joint Committee as a platform for sharing major management issues by environmental category. Through this, site managers, employees, and partner companies are empowered to enhance their practical capabilities in environmental management.

2024 Environment Education Results

| Programs | Participants | 2024 Training Results |

|---|---|---|

| ISO 14001 Internal Auditor and Working-Level Staff Training | Department personnel in charge | May (134) |

| Environmental Education for Operations Departments | On-site operations department leaders, Plant leaders, Dedicated environmental personnel |

February, April, September (408) |

| Environmental Education for Maintenance Departments | Part leaders, Foremen | June (372) |

|

Environmental Education for Investment Departments |

Responsible personnel |

November (165) |

|

Environmental Education for Environmental Departments |

Responsible personnel |

December (35) |

|

Environmental Training for New Hires |

New hires |

As needed |

Environmental Investment

Environmental Investment Performance (2019~2024)

| Category | Highlights | Performance |

|---|---|---|

| Air Quality Improvement |

|

1,994.1 |

| Water Environment Improvement |

|

224.0 |

| By-Product Recycling |

|

21.9 |

|

Others(Chemicals, soil, etc.)

|

|

29.4 |

|

Total |

2,269.4 |

|